pigment yellow 83

Pigment Yellow 83

CAS: 5567-15-7

Molecular Formula: C36H32Cl4N6O8

pigment yellow 83 - Names and Identifiers

| Name | Pigment Yellow 83 |

| Synonyms | PY-83 21108 C.I. 21108 Pigment Yellow 83 PIGMENT YELLOW 83 Permanent Yellow HR permanent yellow hr C.I.Pigment Yellow83 Solid yellow 2 gs - 2 C.I. Pigment Yellow 83 FAST BRILLIANT YELLOW HR 2,2'-[(3,3'-Dichloro-1,1'-biphenyl-4,4'-diyl)bis(azo)]bis[N-(4-chloro-2,5-dimethoxyphenyl)-3-oxobutanamide] 2,2'-[(3,3'-Dichloro[1,1'-biphenyl]-4,4'-diyl)bis(azo)]bis[N-(4-chloro-2,5-dimethoxyphenyl)-3-oxobutyramide] 2,2'-[(3,3'-dichloro[1,1'-biphenyl]-4,4'-diyl)bis(azo)]bis[n-(4-chloro-2,5-dimethoxyphenyl)-3-oxobutyramide] 2,2'-[(3,3'-dichlorobiphenyl-4,4'-diyl)di(E)diazene-2,1-diyl]bis[N-(4-chloro-2,5-dimethoxyphenyl)-3-oxobutanamide] 2-[2-chloro-4-[3-chloro-4-[1-[(4-chloro-2,5-dimethoxy-phenyl)carbamoyl]-2-oxo-propyl]azo-phenyl]phenyl]azo-N-(4-chloro-2,5-dimethoxy-phenyl)-3-oxo-butanamide |

| CAS | 5567-15-7 |

| EINECS | 226-939-8 |

| InChI | InChI=1/C36H32Cl4N6O8/c1-17(47)33(35(49)41-27-15-29(51-3)23(39)13-31(27)53-5)45-43-25-9-7-19(11-21(25)37)20-8-10-26(22(38)12-20)44-46-34(18(2)48)36(50)42-28-16-30(52-4)24(40)14-32(28)54-6/h7-16,33-34H,1-6H3,(H,41,49)(H,42,50) |

pigment yellow 83 - Physico-chemical Properties

| Molecular Formula | C36H32Cl4N6O8 |

| Molar Mass | 818.49 |

| Density | 1.43±0.1 g/cm3(Predicted) |

| Melting Point | > 300°C (dec.) |

| Boling Point | 876.7±65.0 °C(Predicted) |

| Flash Point | 484°C |

| Vapor Presure | 3.03E-31mmHg at 25°C |

| Appearance | Solid |

| Color | Yellow |

| pKa | 0.76±0.59(Predicted) |

| Storage Condition | Refrigerator |

| Stability | Stable. |

| Refractive Index | 1.628 |

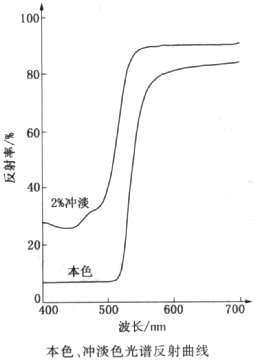

| Physical and Chemical Properties | hue or color: red and yellow relative density: 1.27-1.50 Bulk density/(lb/gal):10.1-12.5 melting point/℃:380-420 average particle size/μm:0.06-0.13 particle shape: acicular specific surface area/(m2/g):49(B3R) pH value/(10% slurry):4.4-6.9 oil absorption/(g/100g):39-98 hiding power: transparent diffraction curve:  reflectance curve:  Red yellow powder. The heat resistance is stable at 200 ℃. Other properties, such as Sun resistance, solvent resistance, acid resistance, alkali resistance are excellent. |

| Use | There are 129 types of this product. Novoperm yellow HR has a specific surface area of 69 m2/g, has excellent light resistance, heat resistance, solvent resistance and migration resistance, and gives a stronger red light yellow than Pigment Yellow 13 (similar to Pigment Yellow 10, the intensity should be 1 times higher). Suitable for all kinds of printing ink and automotive coatings (OEM), latex paint; Widely used in plastic coloring, soft PVC even at low concentrations does not occur migration and bleeding, light fastness 8 (1/3SD), 7 (1/25SD); High color strength (1/3SD) in HDPE, pigment concentration of 0.8%; can also be used for solvent-based wood coloring, Art color, and carbon black to make Brown; The quality of the pigment can meet the fabric printing and dyeing, dry and wet treatment does not affect the color light, to prepare the shape |

pigment yellow 83 - Reference Information

| LogP | 0.02 at 24℃ and pH7 |

| EPA chemical substance information | information provided by: ofmpeb.epa.gov (external link) |

| Introduction | pigment yellow 83, red yellow powder, specific surface area of 69 m2/g, it has excellent light resistance, heat resistance, solvent resistance and migration resistance, giving a stronger red light yellow than Pigment Yellow 13 (similar to Pigment Yellow 10, the intensity is 1 times higher), suitable for all kinds of printing ink and automotive coatings (OEM), latex paint; Widely used in plastic coloring. |

| Application | pigment yellow 83 is a soft PVC that does not undergo migration and bleeding even at low concentrations, light fastness 8 (1/3SD), 7 (1/25SD); High color strength (1/3SD) in HDPE, pigment concentration of 0.8%; can also be used for solvent-based wood coloring, Art color, and carbon black to make Brown; The quality of the pigment can meet the fabric printing and dyeing, dry and wet treatment does not affect the color, in the form of preparation for viscose fiber polypropylene and other pulp coloring. |

| preparation | Step 1: Add 500 parts by weight of deionized water, 70 parts by weight of sodium hydrosulfite, 120 parts by weight of DCB and 180 parts by weight of hydrochloric acid solution, stirring for 4min; Step 2, add a certain amount of ice to the first reaction vessel 1, after cooling the interior of the first reaction vessel 1 to 2 ° C., 50 parts by weight of an aqueous solution of sodium nitrite is put into the first reaction vessel 1, and stirring is performed again to conduct a diazotization reaction, the diazonium liquid is obtained by filtration (the diazotization is relatively complete, the decomposition of sodium nitrite is less, the diazotization of sodium nitrite is carried out at the same time as the nitrogenation of hydrochloric acid, and the complete yield of the diazotization reaction is high); Step 3, add 800 parts by weight of deionized water and 300 parts by weight of phenol AS-IRG (phenol AS-IRG also known as 4-chloro-2, 5-dimethoxyacetoacetanilide) to the second reaction vessel 2, after stirring for 3min, a certain amount of liquid alkali is added, and the temperature in the second reactor 2 is adjusted to 10 ° C. In step 4, 60 parts by weight of glacial acetic acid is added dropwise to the second reactor 2 in the third step, the pH in the second reaction vessel 2 is adjusted to 6, and then the temperature is adjusted to 15 ° C., and the mixture is stirred uniformly to form a coupling solution; Step 5, After stirring for 1-1.5h in step 4, the diazo liquid obtained in step 2 is added to the coupling liquid obtained in step 4. After completion of coupling, the temperature in the second reaction vessel 2 is increased to 80 ℃, and heat preservation 1.5h, after filtration, washing, drying, grinding processing to get pigment yellow 83 pigment crude cake; Step six, the pigment crude filter cake is added to an organic solvent, mixed and stirred evenly, kept for 6 hours, washed with water until neutral, dried at a temperature of 90 ° C., and pulverized to obtain pigment yellow 83 finished product. The diazotization reaction time was 1.5h, the coupling reaction was controlled at 40 C under the condition of micro negative pressure, the coupling reaction time was 2h, and the final pH value was 7 after the completion of the coupling reaction. |

| Application | mainly used for coloring |

| production method | reaction equation operating method a diazotization reactor was charged with 16.3 of water, 3,3 '-dichlorobenzidine hydrochloride, 35% hydrochloric acid 16kg, cooling to 0~5 deg C, add 25% sodium nitrite solution 28.4, reaction 30min, decolorizing with activated carbon, destroy excess sodium nitrite, filtration, diazonium salt preparation coupling. 2, 5-dimethoxy-4-chloroacetoacetanilide 29.91G was mixed with 40% of water and 10kg of sodium hydroxide, 50kg of sodium acetate was added, and 85kg of formic acid was added dropwise. Coupled with the diazonium salt at 5-10 °c, stirring was continued for 30-60min, the temperature was raised to 90-95 °c and maintained for 30-60min. The product was filtered and dried. |

Last Update:2024-04-10 22:29:15

Supplier List

Product Name: Pigment Yellow 83 Visit Supplier Webpage Request for quotation

CAS: 5567-15-7

Tel: 18301782025

Email: 3008007409@qq.com

Mobile: 18021002903

QQ: 3008007409

Wechat: 18301782025

CAS: 5567-15-7

Tel: 18301782025

Email: 3008007409@qq.com

Mobile: 18021002903

QQ: 3008007409

Wechat: 18301782025

Product Name: pigment yellow 83 Request for quotation

CAS: 5567-15-7

Tel:

Email: mdpigment@163.com

Mobile: 13926051736

CAS: 5567-15-7

Tel:

Email: mdpigment@163.com

Mobile: 13926051736

Product Name: Pigment Yellow 83 Visit Supplier Webpage Request for quotation

CAS: 5567-15-7

Tel: 18301782025

Email: 3008007409@qq.com

Mobile: 18021002903

QQ: 3008007409

Wechat: 18301782025

CAS: 5567-15-7

Tel: 18301782025

Email: 3008007409@qq.com

Mobile: 18021002903

QQ: 3008007409

Wechat: 18301782025

Product Name: pigment yellow 83 Request for quotation

CAS: 5567-15-7

Tel:

Email: mdpigment@163.com

Mobile: 13926051736

CAS: 5567-15-7

Tel:

Email: mdpigment@163.com

Mobile: 13926051736

View History